Comprehensive Packaging Machine Repair Service for Quick and Effective Fixes

Comprehensive Packaging Machine Repair Service for Quick and Effective Fixes

Blog Article

Understanding the Trick Parts and Repair Work Strategies for Packaging Equipment Upkeep

Reliable upkeep of packaging makers hinges on an extensive understanding of their crucial elements, including the frame, drive system, and securing systems. Acknowledging usual upkeep concerns, paired with the application of preventative strategies and troubleshooting techniques, can dramatically enhance maker reliability.

Secret Parts of Packaging Devices

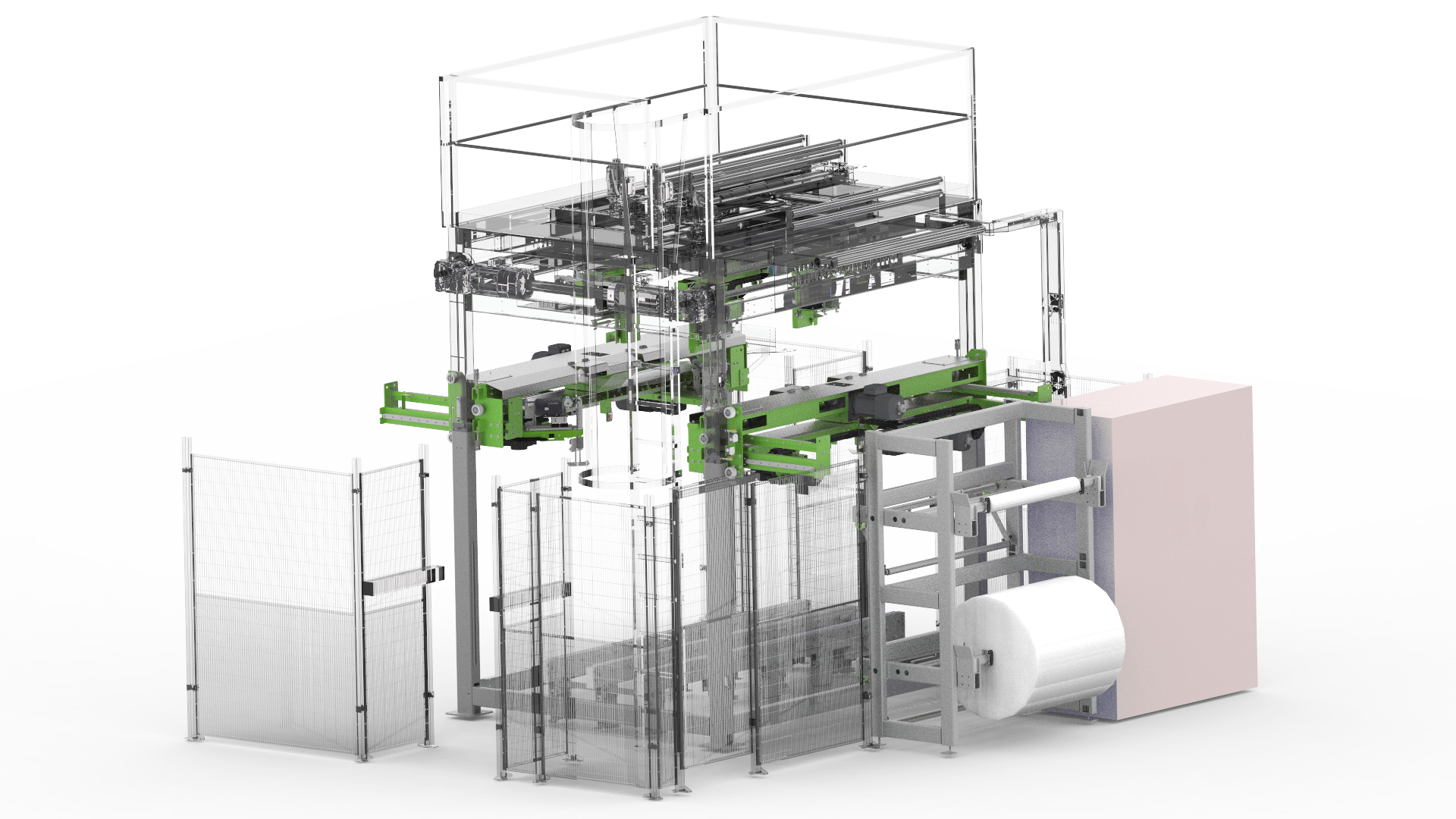

Product packaging makers contain numerous crucial parts that work with each other to guarantee effective and efficient product packaging procedures. At the core of these equipments is the framework, which provides structural integrity and houses the various operating components. The drive system, typically a combination of electric motors and gears, facilitates the activity of elements, enabling exact operation throughout the packaging cycle.

One more essential part is the conveyor system, which transfers items through different stages of the packaging procedure. This is often matched by sensing units and controls that keep an eye on the position and speed of items, making sure synchronization and lessening errors. The loading system is vital for accurately dispensing the right quantity of product right into plans, whether in liquid, powder, or strong kind.

Securing mechanisms, consisting of warmth sealants or glue applicators, play a crucial role in protecting bundles, preventing contamination and prolonging service life. Additionally, classifying systems are integral for offering essential item information, making sure conformity with regulations. The control panel, outfitted with user-friendly user interfaces, permits drivers to handle equipment functions, screen efficiency, and make adjustments as needed, ensuring optimum performance and effectiveness in product packaging procedures.

Usual Upkeep Concerns

Effective operation of product packaging devices depends heavily on routine maintenance to stop typical concerns that can interrupt manufacturing. Among these issues, mechanical damage prevails, particularly in elements like conveyors, motors, and seals, which can result in unforeseen downtimes. In addition, misalignment of components can cause ineffective operation, creating items to be improperly packaged or harmed during the process.

Another usual upkeep problem includes the buildup of dirt and debris, which can disrupt the equipment's sensing units and relocating parts. packaging machine repair service. This not just impacts performance however can likewise position safety dangers. Lubrication failings can lead to increased friction, resulting in getting too hot and eventual part failing.

Electrical troubles, commonly stemming from loosened connections or damaged electrical wiring, can interrupt machinery functions, resulting in significant production delays. Last but not least, software program glitches as a result of inappropriate arrangements or outdated programs can hinder the device's operation, demanding instant intervention. Addressing these common upkeep issues proactively is crucial for ensuring ideal performance and durability of product packaging machinery.

Preventative Upkeep Strategies

Applying preventative maintenance techniques is essential for maintaining the performance and integrity of product packaging equipments. These strategies include an organized technique to maintenance, concentrating on the regular examination and maintenance of equipment to preempt prospective failures. By sticking to a set up maintenance program, drivers can determine wear and tear on components prior to they bring about substantial failures.

Crucial element of a preventative upkeep approach include routine evaluations, part, lubrication, and cleaning substitutes based on maker recommendations. Using checklists can simplify this procedure, guaranteeing that no vital jobs are neglected. Additionally, maintaining exact records of upkeep tasks help in tracking the machine's performance in time, facilitating educated decision-making pertaining to future maintenance demands.

Training team on the significance of preventative upkeep improves conformity and fosters a culture of proactive care. Applying an browse around this site anticipating upkeep element, making use of information analytics and sensor modern technology, can further maximize equipment efficiency by anticipating failures before they take place.

Troubleshooting Techniques

When confronted with malfunctions or ineffectiveness in product packaging equipments, employing organized troubleshooting techniques is essential for determining and settling problems quickly. The primary step in efficient troubleshooting is to establish a clear understanding of the machine's functional criteria and efficiency metrics. This involves examining the maker's requirements, as well as any kind of error codes or informs presented.

Next, drivers must perform a visual evaluation, looking for noticeable indicators of wear, imbalance, or damages. This frequently consists of checking out belts, gears, and sensing units to determine possible sources of breakdown. Gathering functional information, such as production prices and downtime logs, can additionally supply understandings into repeating issues.

Once possible issues are recognized, using a sensible method to separate the source is crucial. This might call for screening specific elements or systems in a regulated manner. Taking part in conversations with drivers who connect with the equipment frequently can produce useful comments regarding unusual habits or patterns.

Repair Work and Replacement Ideal Practices

A detailed understanding of repair and substitute finest techniques is important for keeping the longevity and effectiveness of you can find out more product packaging equipments. On a regular basis examining the condition of equipment elements enables prompt treatment, avoiding even more considerable problems that can cause expensive downtimes.

When repairs are needed, it is crucial to use OEM (Original Tools Producer) components to ensure compatibility and efficiency. This not only maintains the stability of the equipment yet also maintains warranty agreements. In addition, it is advisable to preserve a stock of crucial spare parts to promote quick replacements and decrease operational disruptions.

For complex repair services, engaging certified specialists with specialized training in packaging equipment is advised. They have the knowledge to diagnose issues precisely and perform fixings efficiently. Additionally, recording all repair service tasks and components replacements is critical for maintaining an extensive maintenance history, which can help in future troubleshooting.

Last but not least, implementing a proactive approach, including routine examinations and anticipating upkeep strategies, boosts the reliability of packaging makers. By adhering to these best methods, businesses can make sure ideal maker efficiency, minimize operational risks, and expand tools life-span.

Final Thought

In verdict, an extensive view website understanding of product packaging machine components and effective upkeep strategies is important for ideal efficiency. By implementing these practices, organizations can make sure the long life and efficiency of packaging machines, ultimately contributing to improved operational efficiency and decreased expenses (packaging machine repair service).

Reliable upkeep of product packaging makers pivots on a complete understanding of their vital components, including the framework, drive system, and sealing mechanisms.Effective operation of product packaging equipments counts greatly on normal upkeep to stop typical problems that can disrupt production.Carrying out preventative upkeep approaches is critical for maintaining the effectiveness and dependability of packaging machines. In addition, maintaining exact documents of maintenance activities help in tracking the maker's performance over time, helping with informed decision-making regarding future upkeep requirements.

Report this page